-

322 Views

shares

In automated facilities, floor flatness is not a finish detail it is a system performance requirement.

In automated warehouses, the concrete slab is no longer a passive surface. It is an active performance component that directly affects robotics accuracy, rack stability, equipment lifespan, and overall operational efficiency. One of the most misunderstood and most critical elements of slab performance is FF/FL tolerances.

FF (Floor Flatness) and FL (Floor Levelness) values define how smooth and level a concrete floor is over measured distances. While these numbers may seem abstract on drawings, their real-world implications are significant. In facilities using automated storage and retrieval systems (AS/RS), AMRs, AGVs, or very narrow aisle (VNA) forklifts, inadequate FF/FL performance can lead to navigation errors, increased wheel wear, sensor misreads, rack sway, and unplanned downtime.

Many industrial floors are still designed using legacy tolerances suitable for conventional forklifts and manual operations. However, automation introduces tighter operational envelopes. Robots rely on predictable floor profiles for guidance, speed control, and load stability. Even small deviations in flatness or levelness can compound over long travel paths, especially in high-density racking environments.

The challenge is that FF/FL requirements are often misunderstood, improperly specified, or incorrectly tested. In some cases, tolerances are listed on plans without alignment to the actual automation system. In others, floors are poured without a defined testing protocol, leaving owners exposed to performance risk after installation.

Understanding FF/FL tolerances and how they apply specifically to automated facilities is essential for engineers, general contractors, and facility owners. This knowledge allows teams to align slab design, placement methods, testing standards, and acceptance criteria with the real operational demands of the building.

This article explains what FF/FL tolerances mean, how they are measured, and why they matter in automation ready environments. More importantly, it clarifies common mistakes and outlines best practices to ensure concrete floors support not limit modern warehouse automation.

What Are FF and FL Tolerances in Concrete Floors

FF (Floor Flatness) measures the bumpiness or smoothness of a concrete surface over short distances, while FL (Floor Levelness) measures how much the floor slopes or tilts over longer distances. Together, these values quantify slab surface quality in a standardized, measurable way.

FF is most sensitive to localized surface irregularities such as ridges, dips, or trowel marks. FL captures broader elevation changes that affect how equipment tracks over long runs. Both are expressed as numerical values higher numbers indicate better performance.

FF/FL values are not visual standards. A floor can appear smooth to the eye and still fail flatness or levelness requirements when measured instrumentally. This distinction is critical in automated facilities, where performance depends on measurable geometry, not appearance.

Why FF/FL Tolerances Matter in Automated Facilities

Automated systems interact with the floor continuously. AMRs and AGVs rely on consistent wheel contact and predictable elevation changes to maintain speed, accuracy, and sensor alignment. Excessive flatness deviations can cause vibration, misalignment, and premature mechanical wear.

In VNA and AS/RS environments, levelness is even more critical. Mast-guided forklifts and high-bay racking systems amplify small floor slopes into significant stability issues at height. Poor FL values increase rack deflection, load sway, and safety risk.

Unlike manual operations, automation offers little tolerance for variability. Floors that fall outside required FF/FL ranges can limit system speed, force reprogramming, or require costly corrective grinding after installation.

Typical FF/FL Requirements for Automation-Ready Floors

Standard industrial slabs often target FF 25–35 and FL 20–25. These values are generally sufficient for conventional forklifts but are rarely adequate for automated operations.

Automation-ready facilities typically require significantly higher tolerances, depending on the system:

- AMR / AGV environments may require FF 40–60+

- VNA forklift aisles often demand defined or higher FL values

- AS/RS zones may require aisle-specific tolerances rather than global averages

How FF/FL Testing Is Performed and Interpreted

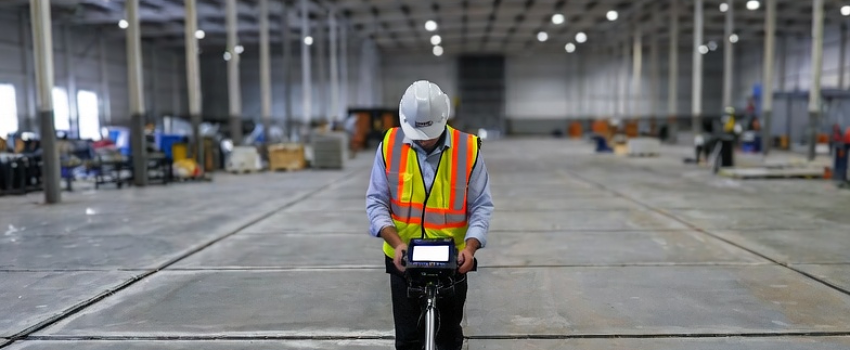

FF/FL testing is performed using instruments such as profilers or digital floor measurement systems that collect elevation data at defined intervals. The data is analyzed statistically to calculate FF and FL numbers for specific test sections.

Testing must follow recognized standards, such as those published by ASTM, and must be conducted within the required time window after placement. Improper timing, insufficient sample size, or incorrect test locations can invalidate results.

Equally important is interpretation. Passing global averages does not guarantee acceptable performance in critical aisles. Automated facilities often require defined area testing, where tolerances are enforced within specific zones rather than across the entire slab.

Common FF/FL Mistakes in Warehouse Construction

One of the most common mistakes is specifying FF/FL values without understanding how they relate to the automation system. Another is assuming that conventional finishing methods will achieve high-tolerance results without specialized placement planning.

Other frequent issues include:

- Testing too early or too late

- Ignoring aisle-specific requirements

- Failing to coordinate joint layout with testing zones

- Relying on visual inspection instead of measured data

These errors often surface only after automation is installed—when correction is most expensive.

Best Practices for Meeting FF/FL Requirements in Automated Floors

Successful automation-ready slabs start with early coordination. Engineers, GCs, flooring specialists, and automation vendors must align on tolerances before construction begins.

Best practices include:

- Defining FF/FL requirements by zone or aisle

- Planning placement sizes and joint layouts accordingly

- Using experienced flatwork crews familiar with high-tolerance slabs

- Performing independent, documented FF/FL testing

- Addressing deviations immediately, before systems are installed

When treated as a performance system not just a concrete pour FF/FL tolerances become a controllable, verifiable part of warehouse success.